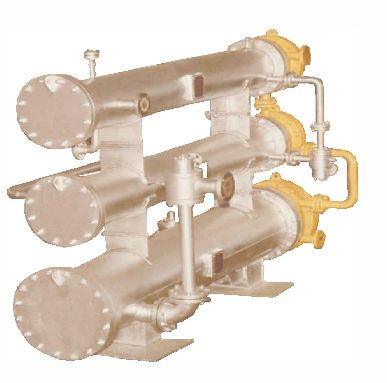

Heat Exchanger

Principle - A heat exchanger is a device built for efficient heat transfer from one medium to another, whether the media are separated by a solid wall so that they never mix, or the media are in direct contact.

Product Range -

- Fixed Tube Sheet

- Floating Head

- U Tube

- Double Pipe

- Kettle

Features -

- Heat Exchanger is available up to Surface area of 2750 m2

- Tube sheet thickness up to 150mm

- Highest sealing get through electronically controlled precision tube expander.

Design Standard and codes -

- ASME Sec VIII with and without "U" Stamp

- TEMA

- ISS 4503

- ISS 2825

- HEI

- PED

- AD MERK

Material of Construction -

- Stainless Steel

- Carbon Steel

- Alloy Steel

- ADM-Brass

- Graphite

- Other Exotic Materials

Design and Manufacturing consideration during Manufacturing of Heat Exchanger

- Tube to Tube - sheet joint

Tube to Tube Sheet Joint -Tube to tube sheet joint has the single objective of sealing against inter leakage between tube side and shell side fluids. The type of tube-to-tubesheet joint to be employed is thus largely dictated

by the anticipated difficulty in providing a reliable seal. Factors which influence the evaluation of the difficulty of providing a reliable seal at the tube-to-tube sheet joint include the following

Tube to Tube Sheet Joint

- Leak characteristics of either the tube side or shell side fluids. hydrogen and Dowthern 'A, are typical of two fluids with high leak characteristics.

- Differential pressure across the tube-to-tube sheet joint.

- Operating temperature to which the tube-to-tube sheet joint will be subjected.

- Relative hazard of inter leakage between the tube side and shell side fluids.

- Frequency and magnitude of cyclic service to which the tube to tube sheet joint will be subjected.

- Corrosion characteristics and erosive tendency of the tube side fluid.

- The metallurgy of the tube and tube sheets.

- Industry preference such as utility, refinery, chemical, petrochemical etc.

- Differential pressure stress as determined by the difference in operating pressure between tube side and shell side fluids.

- Axial stresses which may be the result of tension or compression of the tubes. Differential thermal expansion between shell and tubes or between tube passes will develop the axial stress. Similarly tube side pressure will tend to pull the tubes out of tube shell.

- Differential diametric thermal expansion between the tubes and tube sheet.

- Differential axial thermal expansion between the tube and the tube sheet with certain tube to tube sheet joint construction.

- The above briefly summerises factors which influence the selection of a tube to tube sheet joint and stress to which such joint is subjected. The tube to tube sheet joint should be tight against leakage and should have mechanical strength to resist tubes being pulled or pushed out of a tube sheet.

Electrical Tube Expander -

- Uniform Expansion

- Maximum safe guard to Tube Sheet result to no increase in Diameter or distortion of plate

- Reduced corrosion hazards

- Tube elongation reduced to minimum

- Improved quality of expansion process.